FROM DOWN TO WOOL

A Significant Step Toward Transparency and Sustainability for Recycled Down and for Your Brand

In a world increasingly shaped by circular values and a collective drive toward zero waste, innovation often begins with a simple question: What if we stopped seeing leftovers as waste, and started treating them as resources? This philosophy has guided Re:Down since its creation, and now, it fuels the launch of Re:Wool®, a new high-performance insulation made from recycled wool.

Re:Wool® marks a bold new chapter for Re:Down®, broadening our offer to fashion and apparel brands that are looking for sustainable alternatives to virgin insulation materials. Building on our expertise in post-consumer down recycling, we are proud to now offer a natural, biodegradable wool-based solution designed to meet the same rigorous standards of performance, comfort, and sustainability.

Why Re:Wool®?

The fashion and outdoor apparel industries are increasingly seeking high-performance insulation solutions that don’t compromise environmental values. While synthetic insulations often rely on petroleum-based fibers and contribute to microplastic pollution, and virgin natural fibers carry significant resource footprints, Re:Wool® offers a circular, lower-impact alternative.

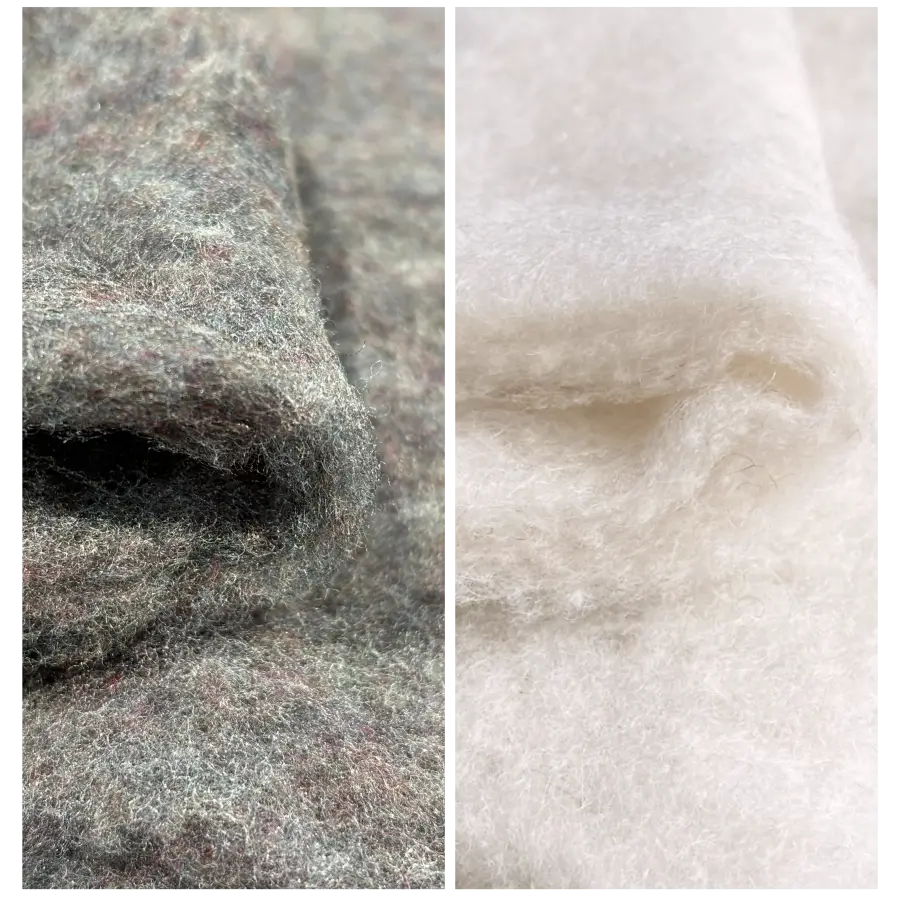

At its core, Re:Wool® is made from post-industrial production scraps collected from spinning mills that specialize in fine wool yarns. These leftover fibers, typically discarded because they are too short to be spun into yarn, still retain the valuable thermoregulatory properties of wool. By reclaiming and transforming this waste, we give it new life as a functional and beautiful insulation product.

From Waste to Warmth: How Re:Wool® Is Made

The journey from spinning mill waste to final insulation layer is both technically sophisticated and environmentally thoughtful.

1. Collection

We begin by sourcing clean, pure wool waste from certified spinning mills. These post industrials scraps are typically generated during the production of high-end yarns and are otherwise too short for spinning

2. Defibration

The wool scraps are then mechanically broken down into fine, fluffy fibers, a process that maintains their natural integrity while making them suitable for insulation use.

3. Blending with PLA

To enhance durability and maintain structure, the recycled wool is blended with 20% PLA (polylactic acid), a bio-based, compostable fiber derived from corn sugar. The result is a product that is not only warm and breathable but also fully biodegradable and free of synthetic microplastics.

4. Wadding and Finishing

The blended fibers are processed into a web through layering and thermal bonding, forming a stable, soft, and resilient insulation layer ready to be sewn into garments.

5. Quality Control & Certification

Each roll of Re:Wool® undergoes strict quality control to ensure consistency in performance and finish. The product carries Global Recycled Standard (GRS) certification, ensuring transparency, traceability, and compliance with environmental and social criteria throughout the supply chain.

Performance Meets Sustainability

Wool has long been celebrated for its ability to insulate while allowing the body to breathe, a quality that synthetic insulations often struggle to replicate. Re:Wool® retains these advantages, delivering what we call “comfortable warmth.” Unlike traditional insulation, which can trap excess heat and moisture, Re:Wool® keeps the wearer warm in cold conditions and dry in humid ones.

Re:Wool® is:

Technical Specifications

Re:Wool® is available in two weights : 60 g/m² and 100 g/m², and comes in two natural colors: mixed grey and off-white. This allows for versatile use across outerwear, midlayers, and fashion insulation pieces.

Shrinkage during washing is minimal (≤3%), and the fiber blend of 80% recycled wool and 20% PLA maintains a 3D structure over time.

Traceability You Can Trust

Re:Wool® isn’t just another recycled insulation. It’s a certified, traceable, premium material developed with the same commitment to transparency and quality that has defined Re:Down from the start.

Re:Down® and Re:Wool® A Natural Extension

The launch of Re:Wool® represents more than a new product, it is an evolution of Re:Down’s broader mission to reduce waste and create valuable new materials from discarded ones. Just as Re:Down pioneered in the revolution on how to use of post-consumer down and feathers in outerwear, bedding, and accessories, Re:Wool® offers a second life to valuable wool scraps, diverting them from landfill and reincorporating them into high-end fashion and outdoor products.

Now, our partners can source both recycled down and recycled wool insulation from a single trusted provider, simplifying sourcing, ensuring certification, and reinforcing brand commitments to circularity and sustainability.

Join Us in Closing the Loop

As sustainability becomes a strategic imperative rather than a marketing trend, brands must look beyond surface-level solutions. The future of fashion is circular, and Re:Wool® is ready to help you meet your material innovation goals, while doing right by the planet.

Re:Wool® is available now for sampling and orders. To learn more or request samples, please contact:

Posted on juin 16, 2025