Why the Global Recycled Standard (GRS)

certification Matters?

A Significant Step Toward Transparency and Sustainability for Recycled Down and for Your Brand

As the fashion and apparel industry continues its shift toward more responsible sourcing, recycled materials have moved from niche to necessity. For brands that rely on down and feather insulation, recycled down offers a sustainable alternative to virgin materials without compromising performance. But how can you ensure the recycled content in your products meets recognized standards of transparency, traceability, and integrity?

This is where the Global Recycled Standard (GRS) comes in and why Re:Down’s GRS certification is a meaningful advantage for your brand.

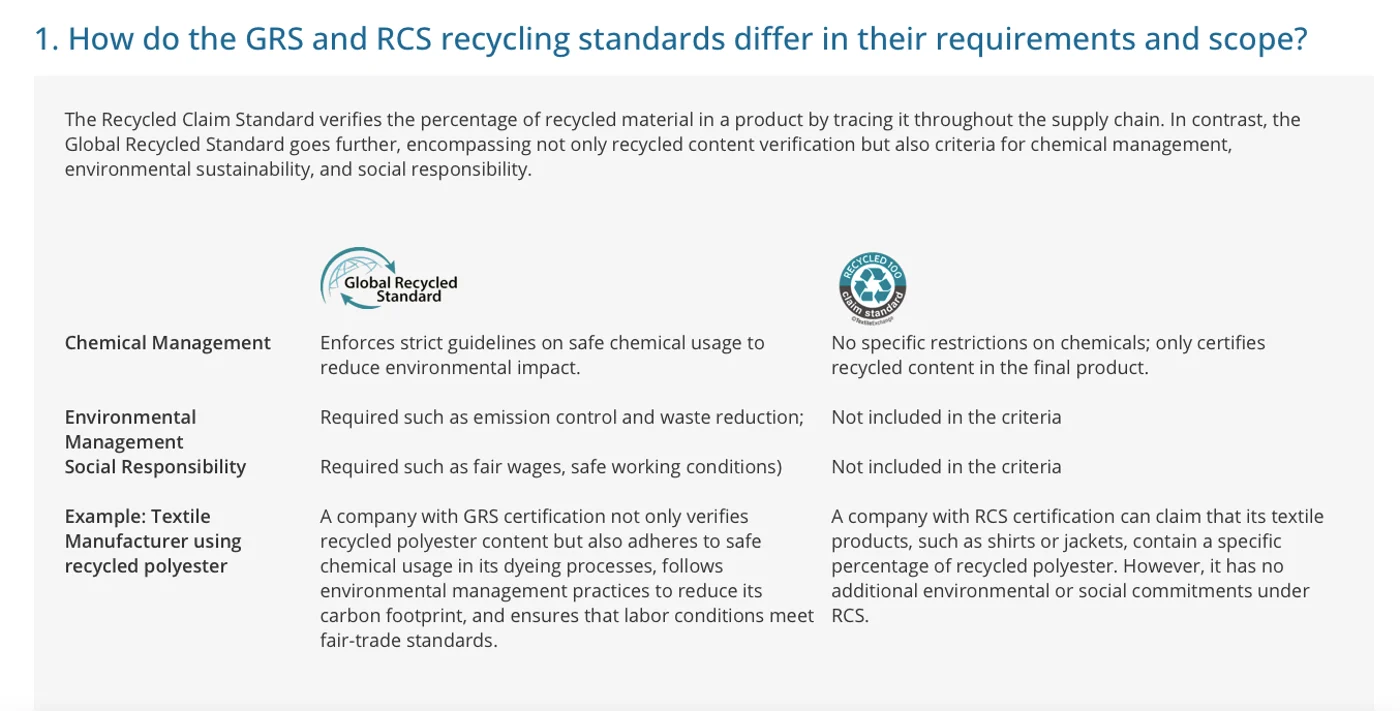

What Is the Global Recycled Standard?

Developed by Textile Exchange, the GRS is an international, voluntary standard that sets requirements for third-party certification of recycled content, chain of custody, social and environmental practices, and chemical restrictions. It covers processing, manufacturing, packaging, labeling, and distribution of products made with recycled materials.

« We believe in materials sourcing that respects our planet, its ecosystems, and its communities ».

Originally founded as Organic Exchange in 2002, Textile Exchange has grown into a global non-profit organization dedicated to accelerating sustainable practices in the textile and fashion industry.

GRS Key Areas of Responsibility:

To display the GRS label, a final product must contain at least 50% certified recycled content, and each recycled input must have a minimum of 20% recycled content. Re:Down goes even further with 100% post-consumer recycled down, professionally collected and processed.

In short, GRS ensures that when a product claims to contain recycled content, it really does and that it has been handled responsibly every step of the way.

For brands, the GRS is more than a label. It’s a signal to consumers, stakeholders, and regulatory bodies that your sustainability commitments are backed by credible, third-party verification.

It’s a key asset for:

Why GRS Matters for Recycled Down?

Recycled down offers clear environmental benefits: it diverts post-consumer waste from landfills, reduces the need for virgin raw materials, and lowers the carbon footprint associated with conventional down sourcing. But until recently, verifying the origin and integrity of recycled down remained a challenge.

GRS provides the framework to trace recycled down through a certified supply chain, from collection to cleaning to final product. For fashion and outdoor brands, this transparency is essential not only for compliance and reporting, but also for storytelling and consumer trust.

As expectations around ESG (Environmental, Social, and Governance) performance rise, especially in the EU and North America, sourcing GRS-certified materials helps brands meet evolving requirements around supply chain due diligence, product labeling, and circularity targets.

Re:Down® is GRS-Certified, Your Trusted Partner in Recycled Down

At Re:Down, we believe that sustainability must be both verifiable and scalable. That’s why we pursued GRS certification for our recycled down supply chain from the start, making us among the first (if not the very first), to certify recycled down under the GRS framework.

Our certification guarantees:

We offer performance-tested recycled down up to 90/10 – 700 fill power, helping brands meet both sustainability goals and product performance expectations. Explore with our Team our full technical specifications.

Textile exchange was Founded as Organic Exchange in 2002, they have grown to become a global non-profit working closely with every sector involved in the fashion and textile supply chain.

Their goal: Incentivizing best practices and managing chain of

custody

Learn more: https://textileexchange.org/responsible-down-standard/

Re:Wool Joins the Movement, GRS-Certified Recycled Wool Now Available

Re:Down’s commitment to certified sustainability now extends beyond down. Our newest product line, Re:Wool®, is also GRS-certified, ensuring full traceability, verified recycled content, and compliance with high environmental and social standards. Re:Wool® high performance insulation is made from production scraps collected from spinning mills that specialize in fine wool yarns. These short-fiber leftovers, which cannot be reused in spinning, are too valuable to discard. By transforming this high-quality post industrial waste into a new recycled material, Re:Down gives wool a second life, without compromising performance or integrity. With GRS certification, brands can now confidently integrate Re:Wool® into their collections and continue building a transparent and credible sustainability narrative.

GRS certification is not a one-time badge, it’s an ongoing commitment. Re:Down & Re:Wool are audited annually by independent bodies to ensure continuous compliance, and we work closely with our partners to support transparency and accountability at every stage.

For you as a brand, this means confidence in your sourcing decisions, and peace of mind when making claims about recycled content in your products.

Strengthening Your Brand’s Sustainability Story

Today’s consumers are more informed and more demanding when it comes to sustainability. Labels, certifications, and third-party validation play an increasingly central role in purchasing decisions.

By partnering with a GRS-certified supplier like Re:Down, your brand can:

Looking Ahead

As the industry moves toward circularity, the role of trusted, certified partners will only grow more important. Re:Down is proud to stand alongside brands that are shaping a more responsible future for fashion one certified fiber at a time.

If you’re ready to strengthen your sustainability strategy with GRS-certified recycled down, our team is here to support you. Let’s build the next chapter together.

Posted on 17 6 月, 2025