Re:wool®

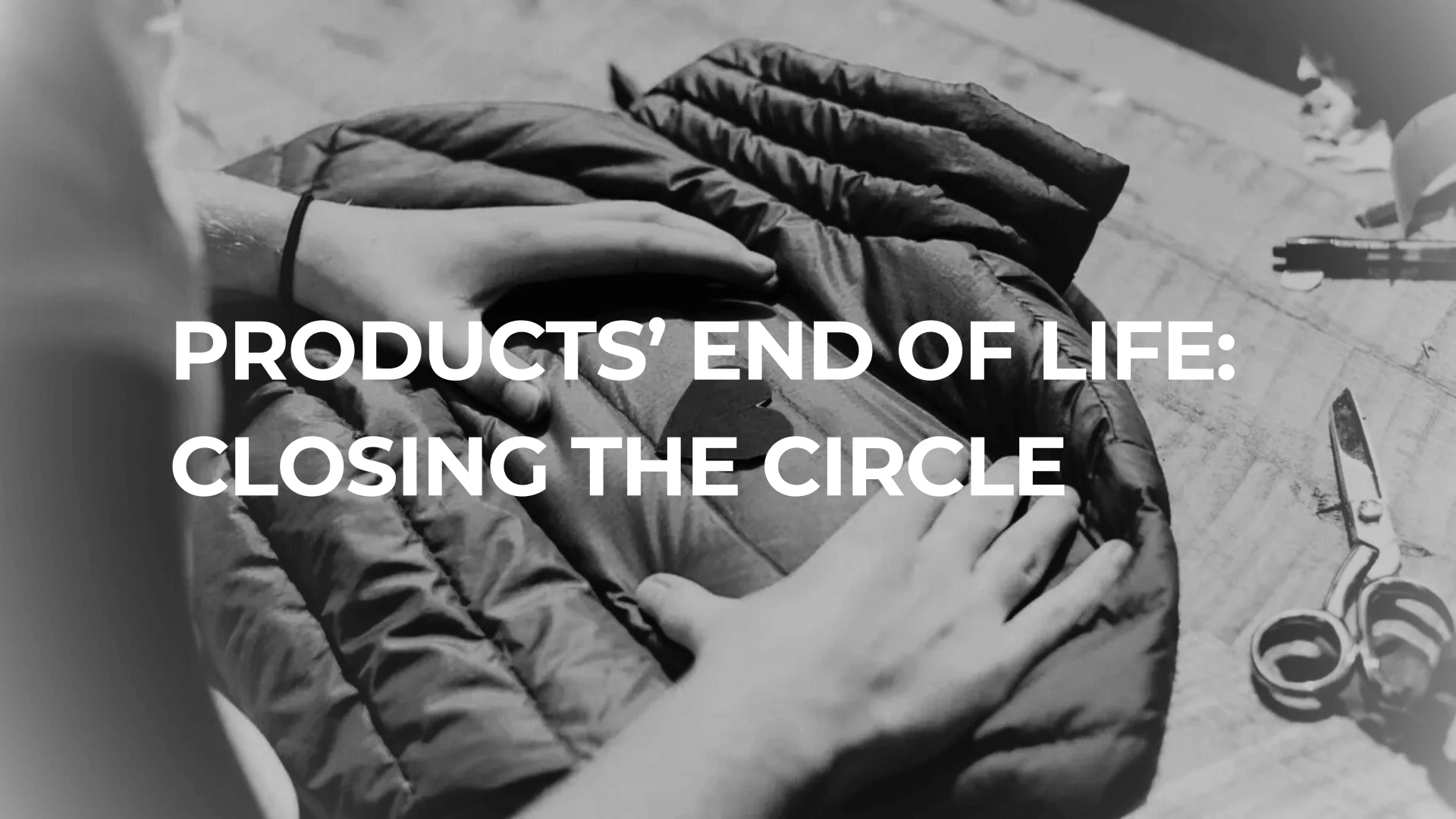

From Wool Leftovers to High-Performance Insulation

Fine wool spinning always produces remnants: short fibres, off-cuts, and production scraps that cannot be re-spun into new yarn. These materials traditionally had little value and often ended up as waste. Re:Wool® offers a different outcome, transforming pre-consumer wool leftovers into a high-performance insulation designed for apparel and gear.

1. Collection: recovering a valuable resource

Re:Wool® starts at spinning mills specialised in fine wool yarns. The fibres left behind are too short for re-spinning, yet described as “too precious to go to waste.” These scraps are collected directly from production, forming a consistent pre-consumer feedstock.

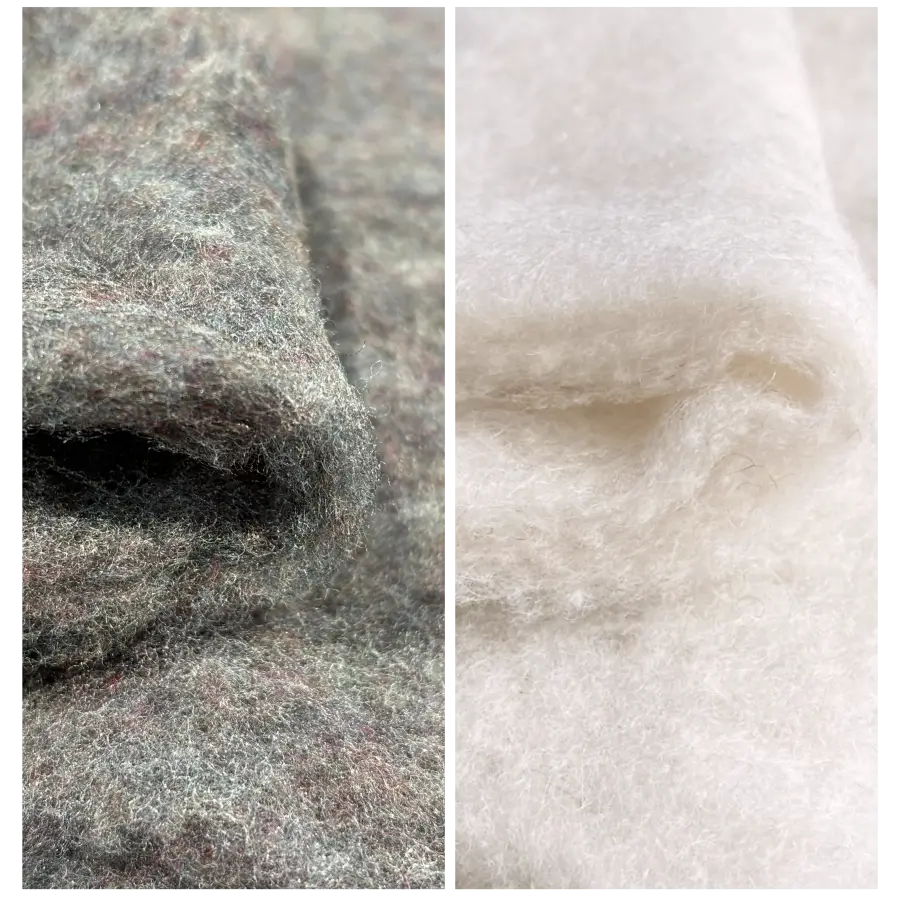

2. Defibration: opening the fibres

The collected scraps go through mechanical defibration, a process where the material is broken down into light, fluffy fibres suitable for non-woven applications.

3. Blending: a precise 80/20 composition

To give the insulation its structure and durability, the recycled wool fibres are blended with 20% PLA, a biosourced fibre made from corn sugar. The remaining 80% is recycled wool. This combination enhances resilience, supports washability, and maintains wool’s natural thermoregulation and breathability.

4. Wadding: worming the insulation web

The wool PLA blend is layered into thin sheets and consolidated through mechanical and thermal processing. This creates a stable non-woven web that can be cut, quilted, or integrated directly into outerwear.

5. Quality Control & Certification

Re:Wool® insulation is available in 60 g/m² and 100 g/m², each tested for thermal resistance, dimensional stability, and wash behaviour. Shrinkage remains below 3% in both directions after washing.

The material meets recognised industry standards:

From waste to performance

By diverting wool production scraps from disposal and repurposing them as insulation, Re:Wool® supports practical circularity: lower waste, reduced use of virgin wool, and a traceable material supply. The insulation offers “comfortable warmth” and leverages wool’s natural thermo-regulation properties, even in humid or damp conditions.

For performance and fashion brands, this approach delivers both functionality and verified sustainability benefits without compromising on comfort, feel, or quality.

This combination provides a recycled, certified, and traceable insulation material that aligns with the expectations of sport, outdoor and fashion brands aiming to integrate circularity into their collections. It supports clear, evidence-based storytelling without compromising on the functional performance required for finished products.

Re:Wool®: Key Advantages for Brands

GRS-certified insulation made from wool sourced at RWS-certified spinning mills.

Provides comfortable thermoregulation and remains effective even in wet conditions.

A biodegradable blend of wool and biosourced PLA, leaving no micro-plastic residues.

Machine-washable at 30°C; PLA maintains the 3D structure for long-lasting performance.

Fibres under 19 microns offer a soft, high-quality touch.

Posted on December 11, 2025